LOGO.S from PASCHAL - a new concept in housing construction - formwork panel with full integrated, folding occupational safety.

To completely comply with the specific features of French housing construction, the LOGO.3 formwork system has been extended to include LOGO.S steel facing and stainless steel facing variants.The LOGO.S formwork system with concrete pressure resistance of up to 100 kN/m² has been specifically designed for housing construction in France to leave just one tie point in the concrete on wall heights of up to 265 cm. With an additional anchor point at the upper end of the panel, a tie can be created 'above the concrete'. This corresponds to just 0.3 tie points/m² in concrete.

For the single-storey sector, the DW15 tie rod is sufficient as an anchor. When concrete pressures are in excess of 70 kN/m², DW20 must be used as tie size.

If wall structures higher than 270 cm are being used with formwork, all LOGO.3 panels can be used in an assembled configuration. In terms of connections, no additional measures are necessary since the wedge clamp, multi-clamp and locking screw are compatible with all systems.

Corner solutions in the system

With system corner solutions, the inside corner post 25x25x270 cm with steel facing is included in the range. This element enables formwork to be installed for right-angled wall constructions.

It almost goes without saying that any kind of angle can be accommodated with the LOGO.S system by using the hinged corner posts from the LOGO.3 range. In this way, artificial concreting sections and unnecessary construction joints are avoided.

Steel and stainless steel formwork facings

Because filler for recesses and fittings for special concrete shaping are fas-tened to the formwork with magnets in France, contractors can choose be-tween the version with a steel formwork facing or the magnetic stainless steel formwork facing. The rear of both steel surfaces is powder-coated and waxed on the shell side. The Multip components are chromated.

Customer requests taken into account

Further development of LOGO.3 to create LOGO.S involved close consultation and collaboration with PASCHAL customers.

The established construction company Boehm BTP SARL also contributed a few ideas and requests. Boehm has been a core customer of PASCHAL for decades, and is a very sought-after construction company in Alsace.

Since the market launch of LOGO.S, the Boehm construction company has used both systems – PASCHAL LOGO.S with steel facing and stainless steel facing in parallel.

Boehm employees are very satisfied with the formwork system that their company purchased in terms of flexibility, handling, speed of work, and with results that are clear to see each time the formwork is erected.

This is a very quick operation too because working with these complete formwork panels dispenses with many minor operations and work steps. Simply because everything needed for formwork construction is available on place and is based on a fully integrated system concept.

Just a few elements that can be combined in many different ways

Just a few elements that can be combined in many different ways

The LOGO.S panel arrangement has also been adapted to the particulars of French construction so as to reduce the number of individual parts to be organised on the site to the absolute minimum.

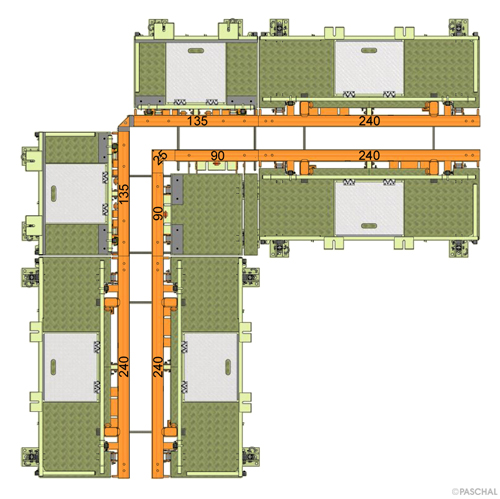

The base panel measures 240x270 cm. In order to simplify the formwork of complete wall structures, the developers and designers at PASCHAL have added two system extras to the LOGO.S: the midi element 135x270 cm, which can also be used as an outside corner element, and the compensation panel 90x270 cm, which can be used as an inside corner panel.

Complete system units

Complete system units

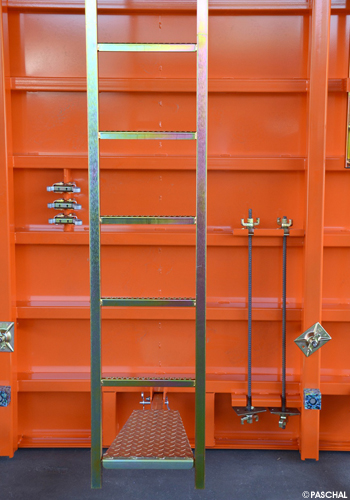

Completely equipped steel formworks with attached connecting pieces, platform brackets with safety installations, props, adjustment spindles and crane lifting clamps are characteristic of the French construction sector. With this in mind, the LOGO.S formwork system features an integrated, folding working platform, “Multip” and, in addition, also includes a ladder for vertical access as well as props to form a complete unit.

There are “stand-by positions” for wedge clamps and other clamping on the rear of the formwork panels.

40 LOGO.S panels similarly used on two construction sites

At the present time, this construction company has 40 LOGO.S formwork panels that it purchased continuously in use. This construction company specialises in structural engineering and in residential construction. For decades, it has only ever employed LOGO.S formwork panels to build concrete walls on two of its construction sites, relying solely on formwork systems from PASCHAL.

Polisher and site foreman Jacky Pareira, and crane operator Luc Schmölker are completely satisfied with LOGO.S formwork. Both of these men are employed by the Böhm construction company, and work together on both of the construction sites in Molsheim. They have nothing but praise for PASCHAL service.

For reasons of design and acoustic insulation, basement walls and load-bearing interior walls are all made of reinforced concrete.

Work started on the building shell structures for the ten phases of this construction project at the end of 2014, and all of this initial work was completed on schedule back in January 2016. C25/35 was used for the strip foundations as well as for the horizontal and vertical concrete constructions.

LOGO.S formwork is being used on all walls on both construction sites in Molsheim.

LOGO.S formwork is being used on all walls on both construction sites in Molsheim.

In some cases, the concrete walls of each separate storey were poured in a single operation using LOGO.S.

In compliance with the specifications of French Work Safety directives, a formwork panel includes fixed-position safety equipment, featuring the foldable Multip work platform with safety rail and ladder, props, adjusting spindles and crane attachment points.

In compliance with the specifications of French Work Safety directives, a formwork panel includes fixed-position safety equipment, featuring the foldable Multip work platform with safety rail and ladder, props, adjusting spindles and crane attachment points.

Each unit is supplemented with stand-by positions for wedge clamps and other clamping.